Description

CNC Flat Steel Clip Punching and Bending Machine: Technical Information

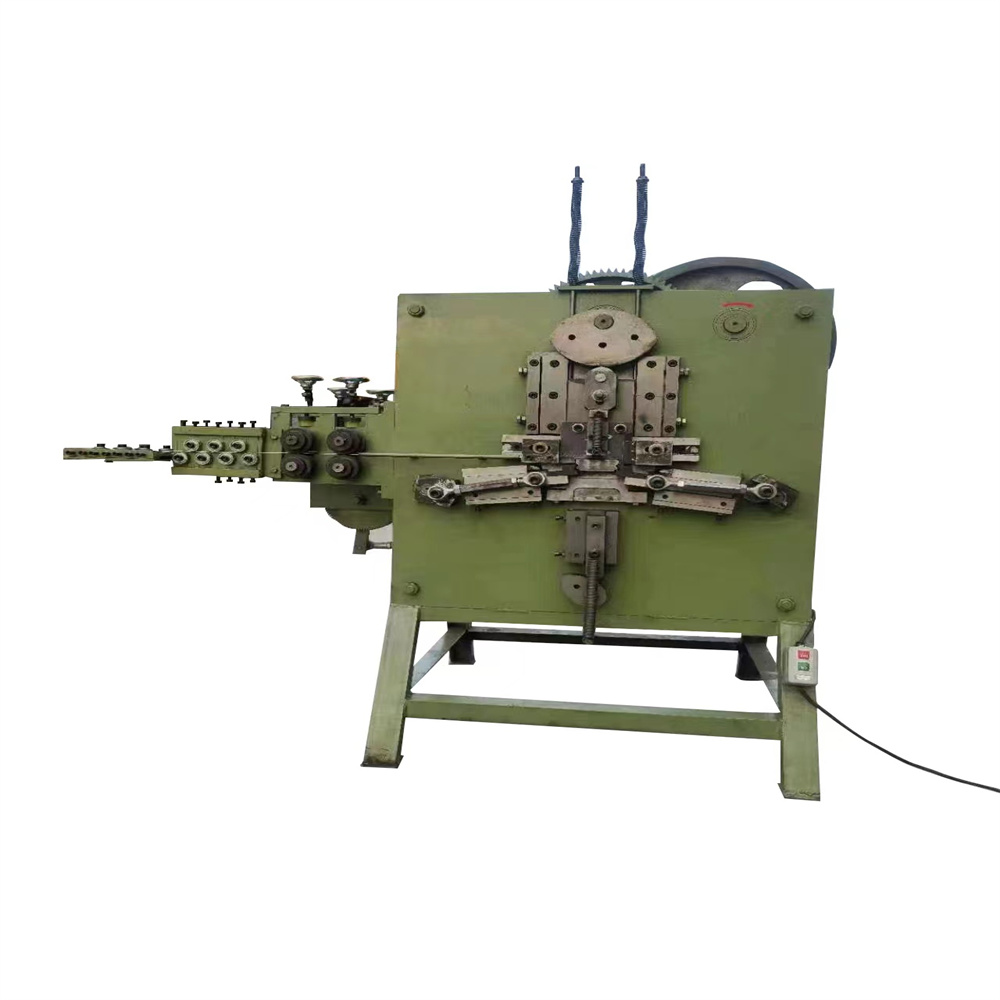

- Control System: Advanced CNC control system with user-friendly interface.

- Punching Capacity: Capable of punching through various thicknesses of flat steel.

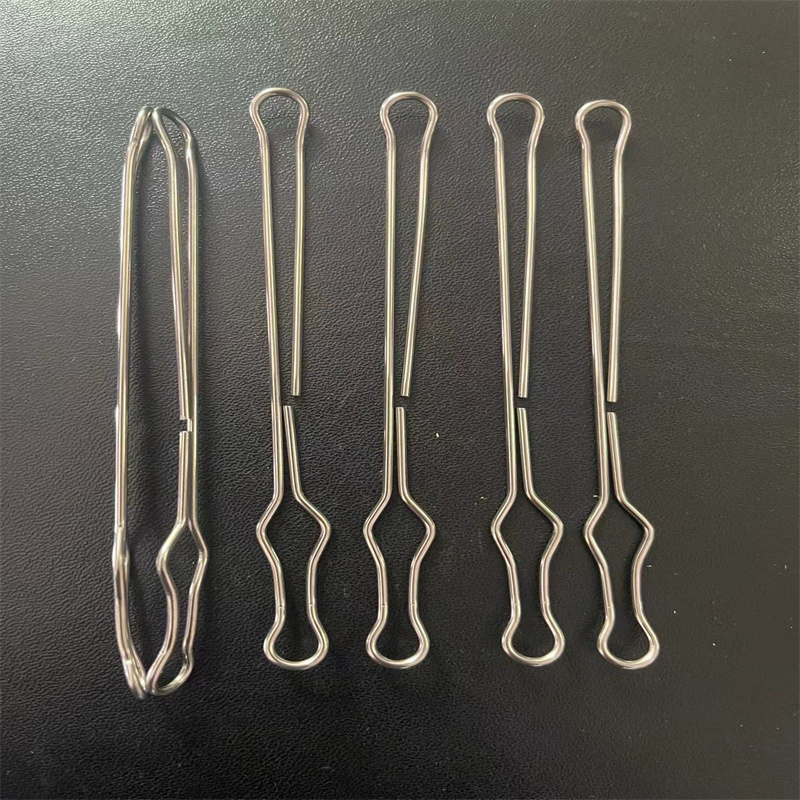

- Bending Range: Adjustable bending angles and radius to accommodate different clip designs.

- Feed System: Automatic feed mechanism for consistent and precise material positioning.

- Tooling: High-quality, durable tooling designed for longevity and minimal maintenance.

- Dimensions: Customizable to fit various production line setups and space requirements.

Advantages of the CNC Flat Steel Clip Punching and Bending Machine

- Precision and Accuracy: The CNC system ensures that each clip is punched and bent to exact specifications, reducing errors and scrap rates.

- Efficiency: Automated processes reduce manual labor, speeding up production and increasing output.

- Versatility: The machine can handle a variety of flat steel materials and clip designs, making it suitable for diverse applications.

- Reliability: Built with robust components, the machine offers consistent performance over long periods.

- Ease of Operation: The user-friendly interface allows for easy programming and operation, even for less experienced operators.

Performance of the CNC Flat Steel Clip Punching and Bending Machine

- Speed: High-speed punching and bending capabilities to meet tight production deadlines.

- Repeatability: Consistent performance ensures that every clip produced meets the same high standards.

- Load Capacity: Capable of handling large volumes of material with minimal downtime for reloading.

- Adjustability: Quick changeover between different clip designs and sizes to maximize flexibility.

Guarantee and Support

- Quality Assurance: Each machine undergoes rigorous quality control checks before leaving our facility.

- Warranty Coverage: Our standard warranty covers parts and labor for a specified period, ensuring peace of mind.

- Technical Support: Access to our team of experts for troubleshooting and advice.

- Maintenance Programs: Optional maintenance and service packages to extend the life of your machine.

- Training: Comprehensive training for your operators to ensure they can get the most out of the machine.