Automatic thread sleeve making machine

1. pipe cutting machine

2. Pipe peeling machine

3. Material uploading machine

4. Double head threading machine

|

Name |

size (mm) |

Equipment technical parameters |

|

Pipe cutting machine |

Host: dimension 1250mm* 1600mm * 1610mm Feed frame: dimension 1500mm width 900mm * 1250mm (2 sets) Feed rack: 3200mm * 900mm * 1250mm |

1. Servo control 2. Processing range: 16 # -32 # 4. Processing efficiency: about 1,000 days / hour (25 #). 5. System: PLC 6. Total power: 11 kW (380V) |

|

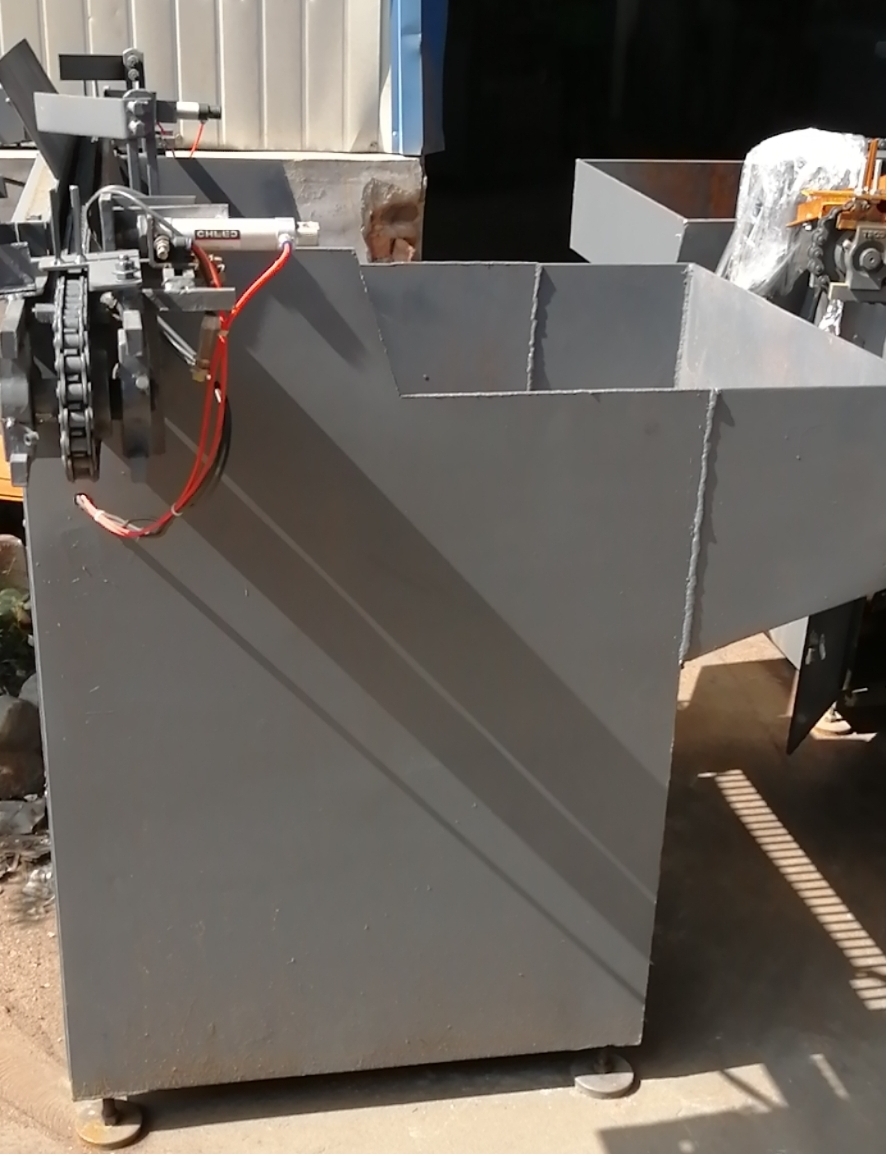

Pipe peeling machine |

dimension 1570 * 800 * 1540 |

1. Motor power: 4KW (380V) 2. Processing range: 16 # -40 # 4. Processing efficiency: greater than or equal to 1000 hours / hour (25 #) 4. System: PLC |

|

Single head material Uploading machine |

dimension 1440mm * 1470mm * 1370mm |

1 Motor power: 120W (380V) 2 Processing range: 16 # -32 # |

|

Single Threading machine |

dimension 1630mm width 560mm * 1630mm |

1.Processing range: 32 # -40 # 2.Processing efficiency: greater than or equal to 400 hours / hour (25 #) 3.system:PLC 4.Total power: 5.5KW |

|

Double head material uploading machine |

dimension 1440mm * 1470mm * 1370mm |

1 Motor power: 120W (380V) 2 Processing range: 16 # -32 # |

|

Double head threading machine |

dimension 1990 * 880 * 1860 |

1.Processing range: 16 # -32 # 2. Processing efficiency: greater than or equal to 600 hours / hour (25 #) 2.system:PLC 3.Total power: 5.5KW

|

|

Logo embossing and bag packing machine |

dimension 1600 * 1250 * 1350 |

1.Processing range: 16 # -40 # 2.Processing efficiency is greater than or equal to 1600 hours / hour (25 #) 3.Motor power: 2.2 kW |

|

Conveyer belt |

dimension 1250 * 510 * 1270 |

Total power: 120W (380V) |

|

Blade sharpening machine |

dimension 450 * 500 * 950 |

Power: 500W |

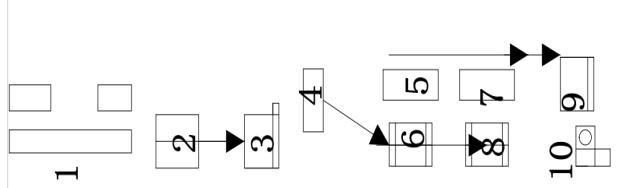

Production line layout

1. Feeder for pipe cutting machine

2. Pipe cutting machine

3. Material uploading machine

4. Pipe peeling machine

5. Pipe uploading machine

6. Double head threading machine

7. Pipe uploading machine

8. Double head threading machine

9. Uploading machine

10. Size emobssing and bag packing machine

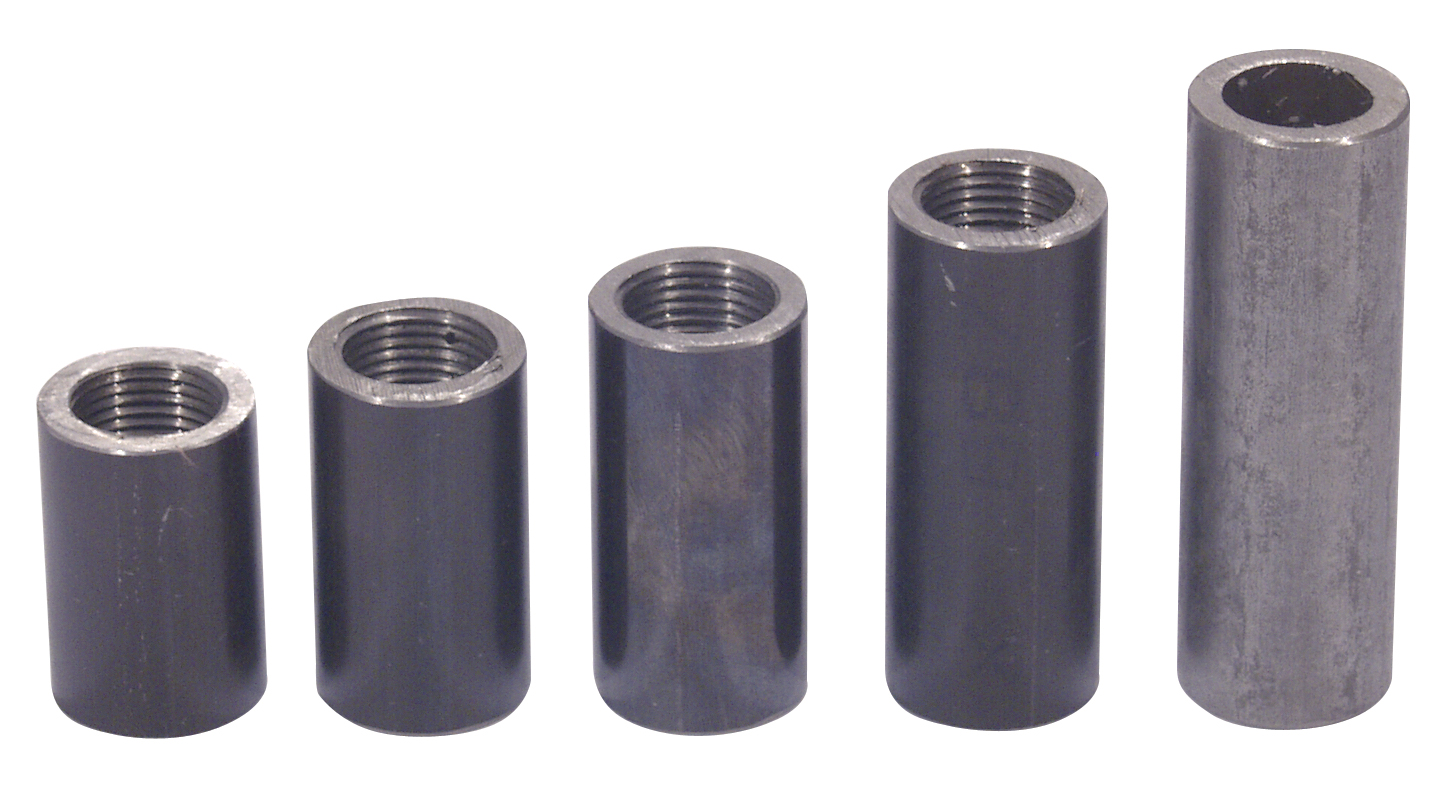

Thread sleeve application

As a multifunctional tool, the sleeve is widely used in many fields. The following are the main uses of the sleeve:

Fixing screws and bolts: The sleeve is usually composed of multiple holes of the same size and is used to fix different types of screws and bolts.

Using as a wrench or sleeve wrench: In daily life, the sleeve is usually used as a wrench or sleeve wrench, especially for turning bolts or nuts with very narrow positions or deep recesses.

Connecting steel bars: The sleeve can also be used as a connector, a special product for mechanical connection of steel bars, such as cold extruded sleeves, tapered thread sleeves and straight thread sleeves. These sleeves can be used to connect ribbed steel bars. They are a must-have hardware tool for home use and have the advantages of easy use and convenient assembly.

Bearing installation: The sleeve can also be used in the process of bearing installation, against the inner ring of the bearing, and after tightening the nail, it reduces unnecessary slippage of the nail and the bearing, so that the bearing can be fully operated, thereby increasing the speed.

Changing thread specifications: The sleeve can change the thread specifications so that it can be matched with parts with other thread specifications.

Contact information for automatic sleeve making machine

Email:sales@metalwiremachinery.com

Mobile/whatsapp:+8615131132009