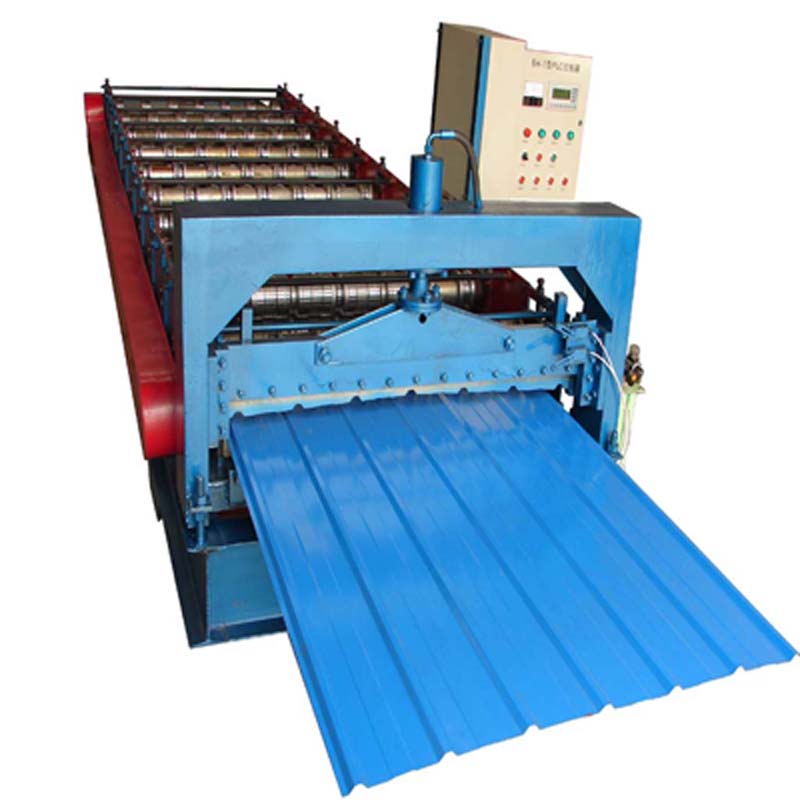

Brief description of the new color steel tile forming machine equipment

1. The first and second generations of "automatic molding color tile pressing machine" use "swing cylinder drive sliding table", "swing cylinder" belongs to "molding color steel tile pressing machine" is "very easy" Damage "accessories, if the forming speed is too fast, the sliding table impact force is large, the buffer is easy to vibrate, resulting in cracks in the tile, which is the "stubborn disease" in the first and second generation color tile pressing machine equipment. Therefore, the molding speed is up to 6 pieces per minute. The "guided four-column molded color steel tile machine" uses the "built-in straight cylinder" slide drive with intelligent hydraulic buffer technology. The sliding table hydraulic buffer can be adjusted freely, making the sliding table run smoothly, safely and reliably.

2. Guided four-column high-speed high-quality fine-color steel tile pressing machine: It adopts a number of advanced technologies, and the main body “body” has no welding, all of which are made of “cast steel”, so the whole machine will not be produced by “welding”. Stress cause the "host" body to deform. The main body "pressure cylinder and main tile mold" is bound by the "guide sleeve" on the 120 mm "four solid-oriented hydraulic props". The "main tile mold" runs vertically up and down without vertical deviation, especially for the main tile mold. The vulnerability absolutely be protected, and the service life of the "main tile mold" is greatly extending.